Fully automatic monitoring of energy systems

The energy concept implemented at REON AG is exemplary in every respect: 322 photovoltaic modules on the roof, 14 electric charging points in the company car park, three public charging points and an electric heat pump to heat the administration building underline the consistency with which REON AG minimises its ecological footprint.

The operating status of the installed systems is continuously monitored so that this can be achieved permanently and without interruption. REON uses the mondas® IoT monitoring platform for this purpose, on which time series data from over 100 data points is recorded and analysed practically in real time. The photovoltaic system, the heat pump, the charging stations and the temperatures in the heating circuits are integrated into the monitoring system.

If, for example, the photovoltaic output drops or the temperatures in the heating circuit are outside the specified tolerances, the system generates qualified alarm tickets. Faults are recognised immediately and can be rectified immediately by the service team. In this way, major, unnoticed yield losses can be completely avoided.

All analysis and monitoring processes run fully automatically in the background. There is no need for any time-consuming troubleshooting. This is an immense advantage, especially for a complex energy supply structure such as REON AG with its many networked energy systems.

Optimising energy flows saves costs.

In addition to the actual technical monitoring, the mondas® IoT platform also offers in-depth analyses of energy flows and thus information for optimised operational energy management.

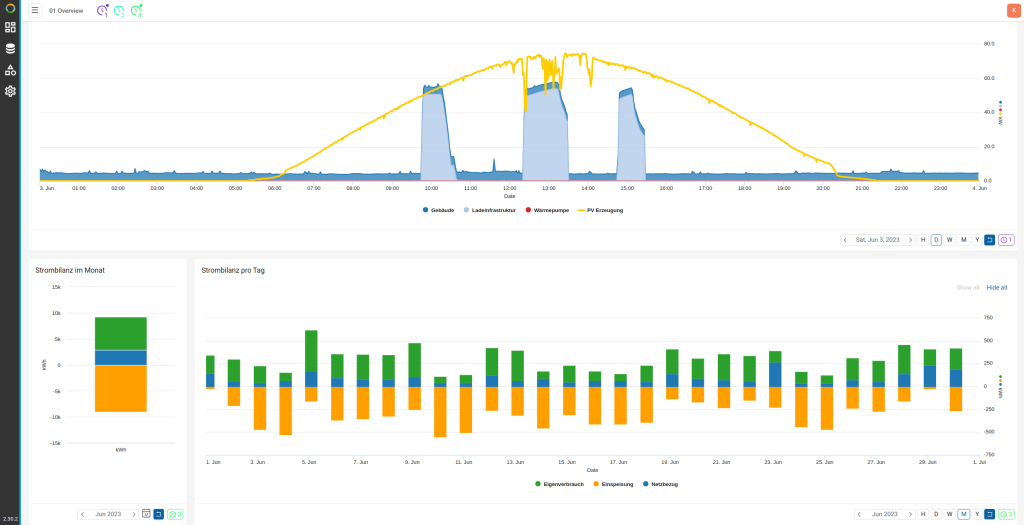

When analysing the electricity load curve at REON AG, for example, the previously suboptimal charging structure of the company vehicles became clear. Employees traditionally plugged their e-vehicles into the company charging stations between 7 and 9 a.m. when they started work. As a result, the battery storage units of the electric cars were already fully charged in the late morning - before the photovoltaic system reached its full capacity.

This was particularly evident on Mondays. The vehicles used at the weekend arrived with practically empty batteries and a correspondingly large "hunger for electricity". A lot of electricity was drawn from the grid during the morning charging process. At midday, when there was plenty of sunshine, the demand was already covered and the solar power generated was fed into the grid for comparatively low feed-in tariffs.

In the meantime, charging processes have been shifted more to lunchtime. The company's own consumption of solar power has increased, while external electricity purchases have been reduced cost-effectively.

Solar-optimised charging behaviour

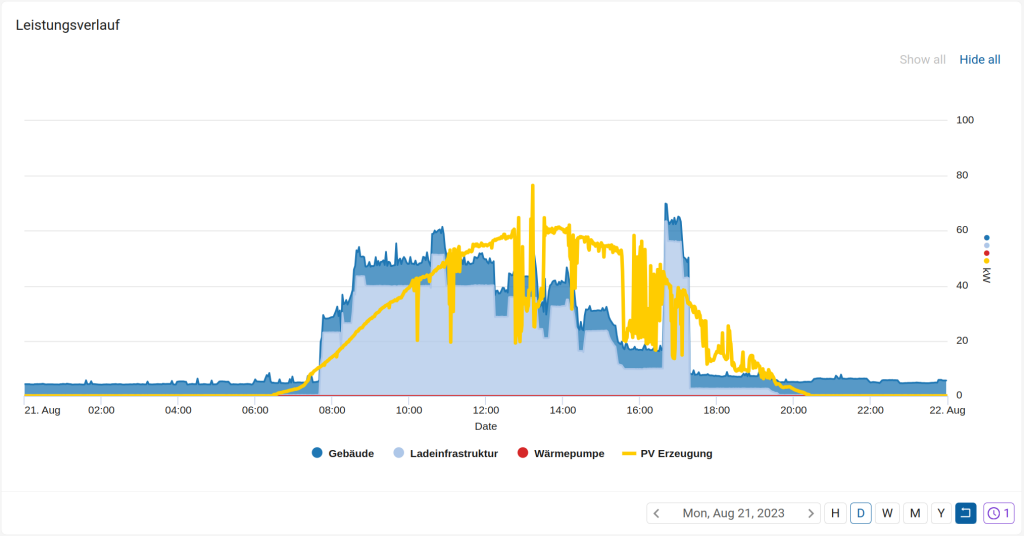

REON AG also wanted to use the mondas® monitoring platform to raise awareness of correct charging behaviour during operation.

The decision was made to also use the info screen in the company foyer to display the current electricity demand and solar power generation. Employees can read off the current photovoltaic output and the charging stations' power consumption on the simple load curve (see graphic below), which is also understandable for non-experts. Anyone can see in passing how much solar power is currently being produced and where it is being consumed. The info screen is noticed: "I actually wanted to use more solar power in my car" or "I rarely have outside appointments on Mondays, so it's enough if the car battery isn't fully charged until the evening" are just some of the comments heard, which document that vehicle users are definitely questioning their charging behaviour and adjusting it accordingly.