The District Heating Network

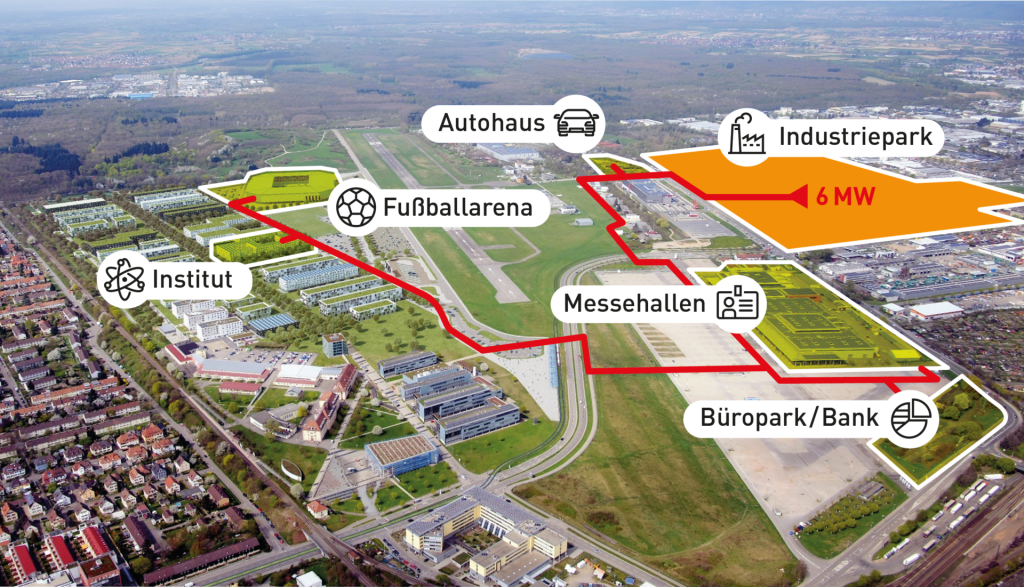

At the centre of the heating network is Cerdia Produktions GmbH in the industrial area of Freiburg-North. The chemical company with 800 employees at the site produces cellulose acetate flakes and tow and has a production-related waste heat potential of 6 MW, which is available all year round and around the clock.

Previously, Cerdia cooled its production processes with well water, which was then recooled and discharged into a stream. Now, however, badenovaWÄRMEPLUS GmbH built a heat transfer station and a local heating network on the Cerdia site, with the aim of connecting as many consumers as possible and supplying them with waste heat (48°C).

The largest heat consumers in the heating network are the new football stadium of the Bundesliga team SC Freiburg and the New Freiburg Trade Fair Centre. Other customers include an administration building of the Freiburg Business and Tourism FWTM, a bank building, a Fraunhofer research institute and a car dealership. Combined, this would result in a peak load of all heat consumers of 8.5 MW, which is 2.5 MW above the maximum available waste heat capacity. This is where the Intelligent Load Management from mondas comes into play.

SC Freiburg Stadium Largest Heat Customer

The largest heat customer in the local heating network is the football stadium of the Bundesliga team SC Freiburg, which opened in October 2021.

There, the heat is needed for hot water production as well as space heating of the cabins and administrative rooms and, above all, for the pitch heating.

The pitch heating system keeps the field free of snow and ice in winter. It is also needed in the transition months and during the growth and maintenance period to ensure the minimum soil temperatures required for professional turf quality.

Exhibition Halls Freiburg

The second largest heat consumer in the network is Messe Freiburg. In “normal times” consumer and trade fairs, major events, concerts and television recordings take place here. More than half a million visitors at around 35 events each year make the fair one of the most important marketplaces in the region.

For the operator – FWTM Freiburger Wirtschaft, Touristik und Messen GmbH & Co. KG – the connection to the waste heat network is just one of many climate protection projects with which it fulfills its exemplary function in climate protection. For example, a 650 kWp photovoltaic system has been installed on the large flat roof since 2006, supplying exhibition halls and conference rooms with environmentally friendly solar power.

How Intelligent Load Management Works

The mondas® IoT platform always keeps an eye on current and future heating requirements. If the heat demand exceeds 6 MW, the waste heat from the steam condensate of the Cerdia and an existing boiler of the exhibition centre can be used as an emergency reserve. However, load management is intended to keep the reserve untouched as far as possible, thus avoiding additional costs for customers.

Based on weather forecasts, event and usage schedules, the mondas IoT platform predicts the heat load of individual consumers. It is therefore known at an early stage where, when and how much heat output will be requested. If the 6 MW limit is threatened to be exceeded, it initiates a load shift. Current measurement data for the individual heat transfer stations and heating circuits, such as heat output, heat quantity, operating temperatures, pressures and operating feedback signals from circulating pumps, are also included in the calculation.

With this data, the mondas® IoT platform creates load forecasts for each individual heat consumer and checks whether the total heat output in the network would likely exceed 6 MW in the next few days.

If this is the case, selected customers are supplied with additional heat in advance. The IoT platform then first sends a “proposal” via its load management controllers to temporarily adjust the setpoint temperatures, which is then increased by a few degrees for a few hours. This allows thermal inertias to be used as temporary heat storage, such as the structural masses of the exhibition halls or the earth layers of the turf heating system.

Operational Sovereignty Remains With the Customer.

Regulation and control “from outside” can quickly seem encroaching for some heat consumers. For this reason, care was taken from the outset in this load management project to ensure that mondas® did not intervene directly in the heating circuit control. Rather, the respective customer building automation system decides whether or not to accept the load management control request. If it refuses, the mondas® IoT platform simply requests the next suitable consumer in the heating network to achieve the desired peak load shift.

If the control request is accepted, the building automation system then switches back to “normal mode” – and reports completion to the platform.

Conclusion

Intelligent load management in the “SC Freiburg” heating network shows that with the help of digitization it is possible to exploit energy-saving potential – in this case waste heat potential – more comprehensively than was previously possible:

Initial calculations show that 15% more waste heat can be used with mondas Intelligent Load Management than would be the case without load management.

The required compliance with the peak load limit and security of supply for the connected heat consumers is achieved at all times.

Thanks to the connection to the waste heat network and the currently completed construction of one of the world’s largest solar power plants on a stadium roof, the SC Stadium can be called a “climate-neutral stadium” in the future.

The waste heat network with load management were put into operation in the autumn of 2021. Future operational experience is continuously included and “learned” in the AI-based algorithms of the IoT platform. The system thus becomes increasingly “intelligent” during operation.